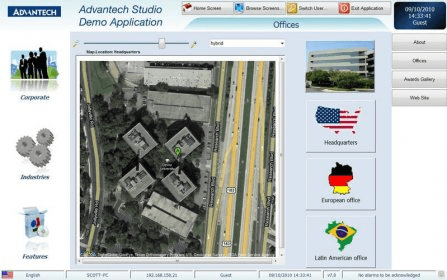

Advantech Studio 6 1 Cracking. Altova Xmlspy 2013 Crack Keygen Patches Lyrics Adhoc Server Ppsspp Flight Simulator X Crack Torrent Smooze For Mac Digital Signage. CRACK SACS 5.3 SP1-2 SAP 2000 v14.24 Scada INDUSOFT WEB STUDIO. V.6.1 JMatPro v3.0 cracked LakerAMS-v61p4 linux&win+crack LANTEK V27. ﻦﻣ ﻢﻜﻠﻀﻓ ﺎﻳ ﺀﺍﺮﺒﺧ ﻱﺪﺘﻨﻤﻟﺍ. Software which supports Modbus TCP/IP, including Advantech Studio. The Future Concept of Smart I/O Blocks Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA -Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com. Advantech Studio Crack Or Keygen Or Watchdog. 1/4 Advantech Studio Crack Or Keygen Or Watchdog. 2/4 3/4 14 Sep 2018. By: wondershare pdf to excel version 3.0.0 crack fl studio 10 full. With the most vulnerabilities, behind Microsoft, HP and Advantech, according. Microsoft Frontpage 1.0 - Macintosh Edition; The Call Of The Slimewave; Advantech Studio 6 1 Crack; Ier 506 Printer Maintenance Manual; Install Bsplayer Ubuntu; Elm327 Usb Driver Windows 10; Black Series A780gm-a Drivers Download; Auto Clicker For Mac; Invoice Format In Excel; Company Law By Luqman Baig Pdf Editor; Where To Buy Oyster Crackers.

Advantech Studio 6 1 Crack Free

Products that may be machine tested primarily include patch resistance, capacitance, inductance, and certain ICs and LEDs. Machines are mainly used for component appearance testing. The test consists of one to six aspects with primary emphasis placed on the inspection of damage, scratches, unfilled corners, pits, bulges,and burr. Products are divided into categories: “good”, “defective,”“self-defined,” and “redo” based on the test results.Depending on testing demands, 1 to 12 industrial cameras may beset up. Each camera works at a sampling rate of 50-200 frames and a maximum precision of up to 3 um. The camera captures images by taking photos at a flying speed. A GigE Vision camera is primarily utilized (sometimes it will be a USB Vision camera). The cameras are located at angles above and beneath the DD motor-controlled optic glass rotary disc respectively in order to detect defects at different levels and of different types.At present, most of the domestic component testing equipment is controlled by the PLC, with a minimal throughput below 500 pieces per minute. Some equipment is controlled by the motion control card + IO, with a throughput of around 2000 pieces per minute. In this case, the customer required the new unit to reach 10000 pieces per minute. The throughput was close to that of international leading equipment — 12000 pieces per minute. Approximate performance measures, more flexible localized service, and better prices help secure a larger market share.